The Challenge

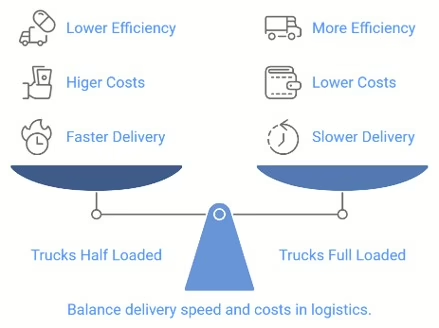

An international logistics company struggles to balance delivery speed with cost.

Half-loaded trucks are faster but increase transport costs and reduce efficiency, while fully loaded trucks take longer, delaying deliveries and causing customer dissatisfaction.

Contradictions

Technical Contradiction

To increase delivery speed, trucks need to be half-loaded (less weight, more space, and higher speed). However, this raises operational costs.

Physical contradiction

Trucks need to be both fully loaded to minimize costs and partially empty to maintain high delivery speed.

We asked to our chatbot to find solutions applying the TRIZ inventive principles

Below the Results

a. Segmentation (Principle 1)

Instead of using large trucks to transport the entire load, the company could divide the load into smaller segments and use smaller, more agile vehicles for local deliveries. For example, large trucks could arrive at regional warehouses, and from there smaller vehicles, such as electric vans, could handle the final deliveries. This reduces costs for long distances and increases speed on short routes.

b. Local Quality (Principle 3)

The load and frequency could be optimized based on local specifics, such as market demand or customer distance, to better meet the needs of each segment.

c. Prior Action (Principle 10)

Deliveries could be planned in advance using predictive technologies that allow anticipating demand and optimizing the load and frequency accordingly.

d. Do it in Reverse (Principle 13)

Instead of waiting for the central warehouse to manage all logistics, deliveries could be planned from the endpoint (the customer) to the starting point. Trucks would depart only when a certain number of orders in a specific area have been received. This reduces unnecessary trips, and trucks would only travel full when there are enough orders in an area.

e. Dynamicity (Principle 15)

A fleet of modular vehicles with additional sections could be adopted. If there is little cargo, the truck travels with just one section, while when there are more orders, modular sections can be added. In this way, trucks never travel half-empty but can dynamically adapt to the volume of orders.

f. Periodic Action (Principle 19)

Instead of making deliveries at a constant speed, the company can organize deliveries at regular intervals to optimize vehicle use. For example, a truck could depart every 2 hours, regardless of load level, ensuring high delivery frequency without waiting for the truck to be full.

g. Continuity of a Useful Action (Principle 20)

Discounted pricing plans for periodic deliveries could be offered.